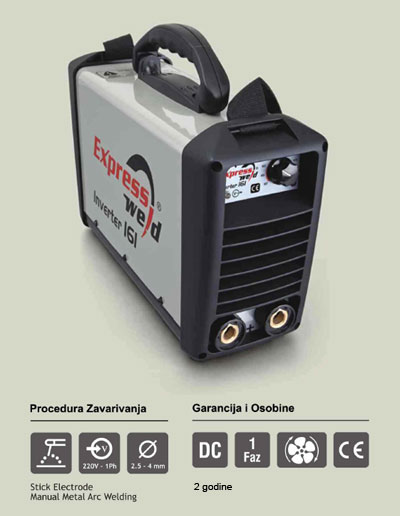

Expressweld Inverter 161

Features and Advantages

- Digital inverter technology

- Ideal for maintenance-repair steel installation workshops and small-size welded construction applications

- Excellent arc characteristics and outstanding performance for rutil and basic electrode types

- Ideal for welding of carbon and low-alloy steels, even stainless steels.

- 220 V, 1Ph input voltage and maximum output current of 160 amps. provide a continuous welding operation with electrodes in diameters of 2,5 and 3,2 mm

- Suitable for operation on site or within workshop environment by providing maximum flexibility

- Weighing only 6 kg.

- Fan cooling

- Thermostatica overload protection and indicator light.

- Easy-to-use and user-friendly control panel.

- Recessed controls and connections designed to help protect controls from damage.

- Two quarter-turn (positive and negative) output terminals for easy cable connection. vvvvvv

- IP21S protection class.

- Meet EN 60974-1 CE standards for safety and reliability.vv

- Two years warranty on parts and labor.

Technical Properties

| EXPRESSWELD | Inverter 161 |

| Input voltage | 220 V; 1~Ph; 50/60 Hz |

| Power input @ rated output | 6,6 kVA (%35) 5,5 kVA (%60) |

| Input current (max.) | 30 A (%35) 25 A (%60) |

| Power factor (cos φ) | 0,74 (%35) |

| Rated output current, voltage and duty cycle |

155 A; 26 V (%35) 125 A; 25 V (%60) |

| Open circuit voltage | 60 V (DC) |

| Current range | 30 - 160 A |

| Fuse size and type | 32 A (retarded) |

| Protection class | IP21S |

| Cooling system | Fan |

| Weight (without cables) | 6 kg |

| Dimensions (W x H x D) | 138 x 260 x 395 |

| Compliance | EN 60974-1; CE |

- 1 Handle

- 2 Thermal protection indicator light

- 3 Rigid plastic front and rear panels

- 4 Negative (-) output terminal

- 5 Welding current control knob

- 6 Positive (+) output terminal

- 7 On/off switch

- 8 Power cable